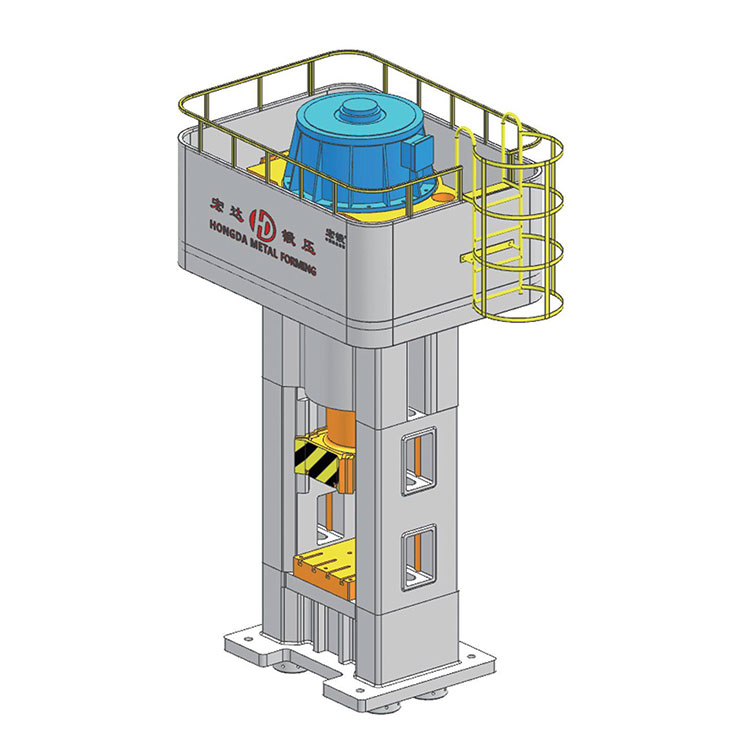

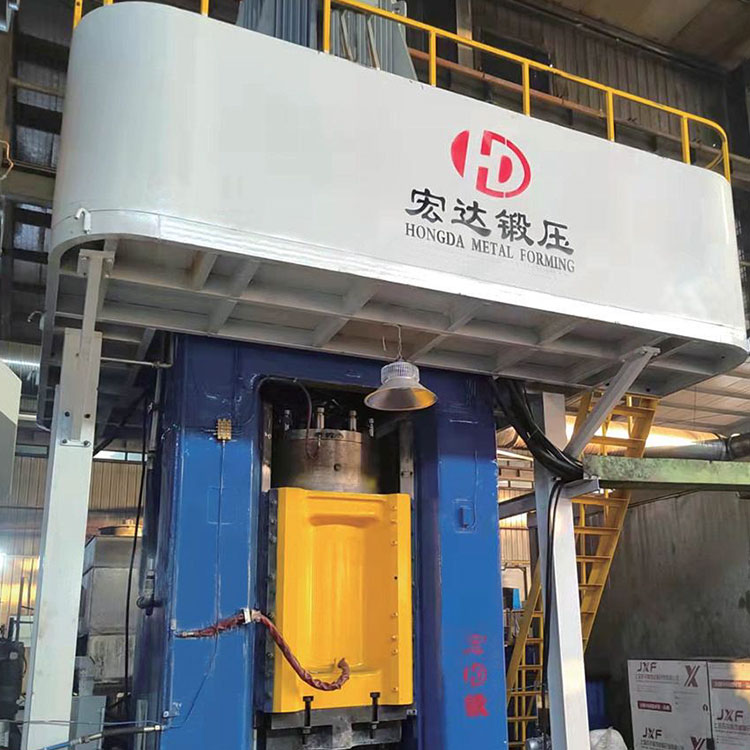

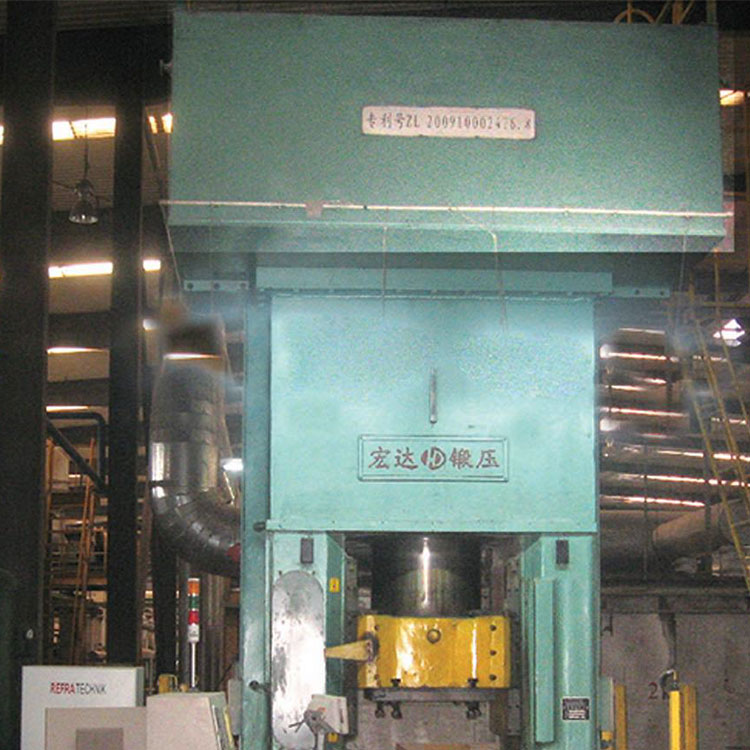

Electric CNC Screw Press with Long Slider EPC Series

HONGDUAN's EPC series long slide CNC electric screw press is assembled using stronger materials than our counterparts, and all assembled components are industry-leading products in China. This product has a long slide and long guide, which is cheaper than EP. row.

Send Inquiry

HONGDUAN EPC series long slide CNC electric screw press is assembled using high quality parts. It is an energy efficient CNC forging equipment with mechanical, electrical and fluid integration. It has a simple structure with side load protection capability and various functions such as precise impact energy control, punching precision, and is easy to operate and maintain. Its electrical system uses digital control and provides automatic forging according to the requirements of the stamping process at multiple stations. It can also create automated forging lines with other auxiliary lines. Compared to a friction press of the same tonnage, the energy savings reach more than 48.5%. It is an ideal forging equipment for aviation, aerospace, weapons, railway, construction machinery and other industries.

HONGDUAN Electric CNC Screw Press with Long Slider EPC Series Parameter (Specification)

| Main settings | Unit | EPC -160A |

EPC -300A |

EPC -400A |

EPC -630A |

EPC -1000A |

EPC -1600A |

EPC -2500A |

EPC -3000A |

EPC -4000A |

EPC -5000 |

EPC -6300A |

EPC -8000A |

EPC -10000A |

EPC -12500A |

EPC -16000A |

|

| Nominal force | KN | 1600 | 3000 | 4000 | 6300 | 10000 | 16000 | 25000 | 30000 | 40000 | 50000 | 63000 | 80000 | 100000 | 25000 | 160000 | |

| Permissible impact force (central loading) |

KN | 2500 | 4800 | 6300 | 10000 | 16000 | 25000 | 40000 | 48000 | 63000 | 80000 | 100000 | 125000 | 160000 | 200000 | 250000 | |

| Energy of a part of motion | kJ | 10 | 26 | 40 | 90 | 160 | 290 | 550 | 600 | 1000 | 1200 | 1600 | 2280 | 4000 | 5000 | 7400 | |

| Ram Stroke | mm | 300 | 380 | 400 | 550 | 550 | 650 | 700 | 700 | 750 | 750 | 850 | 900 | 1000 | 1100 | 1200 | |

| Number move | min-1 | 30 | 27 | 24 | 21 | 18 | 16 | 14 | 14 | 11 | 10 | 8 | 8 | 6 | 5 | 5 | |

| Mini die height | mm | 300 | 430 | 450 | 550 | 560 | 700 | 1050 | 1060 | 1200 | 1200 | 1380 | 1250 | 1700 | 1800 | 2000 | |

| Table pad height | mm | 120 | 120 | 120 | 140 | 180 | 200 | 280 | 280 | 300 | 300 | 320 | 350 | 350 | 400 | 400 | |

| Table Measurement |

Front/Rear | mm | 600 | 700 | 750 | 900 | 1000 | 1200 | 1400 | 1560 | 1900 | 1900 | 2150 | 2600 | 2800 | 2900 | 3000 |

| Left right | mm | 560 | 640 | 700 | 750 | 900 | 1100 | 1250 | 1350 | 1600 | 1600 | 1800 | 2000 | 2400 | 2500 | 2700 | |

| Generally Measurement |

Left right | mm | 2800 | 2800 | 3000 | 4000 | 4400 | 4500 | 5350 | 5350 | 7200 | 7500 | 8200 | 10000 | |||

| Back and forth | mm | 1700 | 1850 | 2600 | 2600 | 3800 | 4200 | 5000 | 5000 | 6800 | 7000 | 7900 | 9000 | 一 | 一 | 一 | |

| Height | mm | 3800 | 4300 | 4500 | 4900 | 5500 | 6300 | 7500 | 8500 | 10000 | 10500 | 11500 | 12000 | ||||

HONGDUAN Electric CNC Screw Press with Long Slider EPC Series Features and Application

1. Slider length

2. Cheaper prices

3. Simple design with side load protection capability.

4. Easy to operate and maintain.

HONGDUAN Electric CNC Screw Press with Long Slider EPC Series Details