China HMP Series Hot Forging Crank Press Manufacturers, Suppliers, Factory

HMP series hot forging crank press is a special equipment used for hot forging process. Through the forging process, they are capable of plastically processing metal blanks with high strength and productivity to create forgings of various shapes and sizes.

HMP series crank hot stamping presses generally have the following characteristics:

1. High productivity: This series of presses adopts advanced transmission and control systems, which can carry out precision stamping operations at high speeds and high temperatures, thereby improving production efficiency and product quality.

2. Large Tonnage: HMP series crank hot forging presses can provide various tonnage options to meet the forging needs of different scale and complexity.

3. Easy to operate and maintain. This series of presses adopts human-computer interface, making the operation easier and more convenient. At the same time, its modular design makes maintenance and repair more convenient and faster.

4. Energy saving and environmental protection: HMP series crank hot forging presses adopt advanced energy recovery technology, which can effectively reduce energy consumption and reduce environmental impact.

5. Wide range of applications. With its high efficiency, precision and flexibility, HMP series hot stamping crank presses are widely used in automobiles, aviation, power generation, mechanical engineering and other fields.

In short, HMP series hot forging crank press is an efficient, precise and flexible forging equipment that can meet the forging needs of various sizes and complexities.

- View as

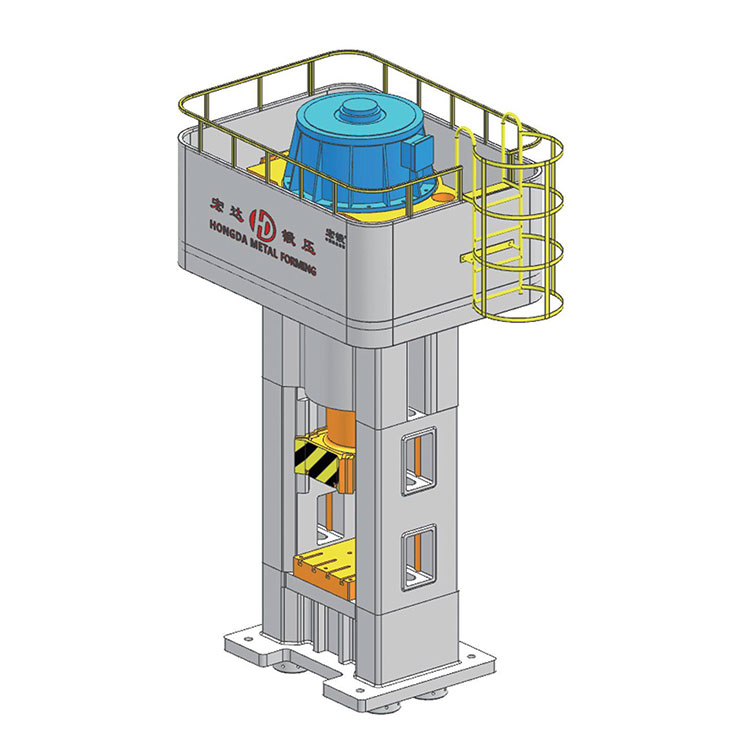

Hot forging crank press HMP-6300

HONGDUAN is a large manufacturer and supplier of HMP-6300 hot forging crank press in China. The market share of our products has been ranked first in China for many years in a row. Our HMP-6300 hot forging crank press has good price advantage. We are looking forward to becoming your long-term partner in China.

Read MoreSend Inquiry